The ULS-200 sensor from Gems Sensors represents a leap in point-level sensing technology, harnessing advanced methods to deliver precise, reliable liquid-level detection across various applications. To appreciate what makes the ULS-200 so effective, let’s dive into the science behind dielectric constant and capacitance—the backbone of its innovative sensing technology.

What is capacitive sensing?

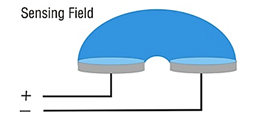

A capacitor is a two-terminal device made up of two conducting bodies separated by a non-conducting (dielectric) material. In dielectric-type capacitive sensors, two sensing electrodes are integrated into a high-frequency oscillator, which produces a periodic electronic signal. As shown in the image below, the sensor’s field projects outward, so when media enters this field, it increases capacitance and triggers oscillation.

With a constant dielectric, capacitance remains steady; however, when the dielectric changes, capacitance also shifts. In the sensor’s "no target" state, the oscillator is at rest, but as a target enters the field and capacitance increases, oscillation begins, and once the amplitude reaches a threshold, a change in signal state is triggered.

What is Dielectric Constant, and Why Does it Matter?

The dielectric constant is a measure of a media's ability to store electric charge when placed in an electric field, directly affecting capacitance. This principle plays a significant role in sensors like the ULS-200, which uses capacitance changes to detect different media and measure liquid levels.

How the ULS-200 Senses Dielectric Constant in Liquids

The ULS-200 operates by measuring variations in capacitance caused by changes in the dielectric constant of liquids. When a liquid enters the sensing field, its dielectric properties alter the electric charge the sensor can hold, enabling precise detection. Factors such as sensor design, measurement techniques, and frequency can all influence the accuracy of these readings, making the ULS-200’s design especially significant for consistent performance.

Factors That Influence Measurement Accuracy

For accurate sensing, the ULS-200 manages key conditions that can influence measurement precision, such as temperature and liquid conductivity. Dielectric constants often fluctuate with temperature, so the ULS-200 compensates for these variations to maintain

accuracy. Additionally, while highly conductive liquids can sometimes impact measurements, the ULS-200 is specifically designed to mitigate these effects, ensuring reliable performance across diverse applications.

Why the ULS-200 Sensor is Unique

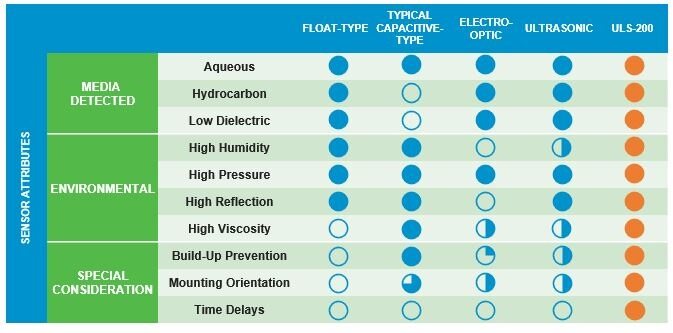

The ULS-200 stands out with its ability to detect both high and low-dielectric liquids, overcoming limitations found in traditional float-type, ultrasonic, or optical sensors. It features pre-configured options to optimize for various dielectric ranges, offering reliable detection across numerous applications. The ULS-200’s advanced sensing technology can be configured for high or low dielectrics, wet or dry signals, sinking or sourcing output, and time delays on rising or falling, making it one of the most adaptable sensors in the market.

By combining the best of what other sensing technologies offer, the ULS-200 sets a new standard for durability, accuracy, and versatility in point-level detection.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER