Ultrasonic Sensing

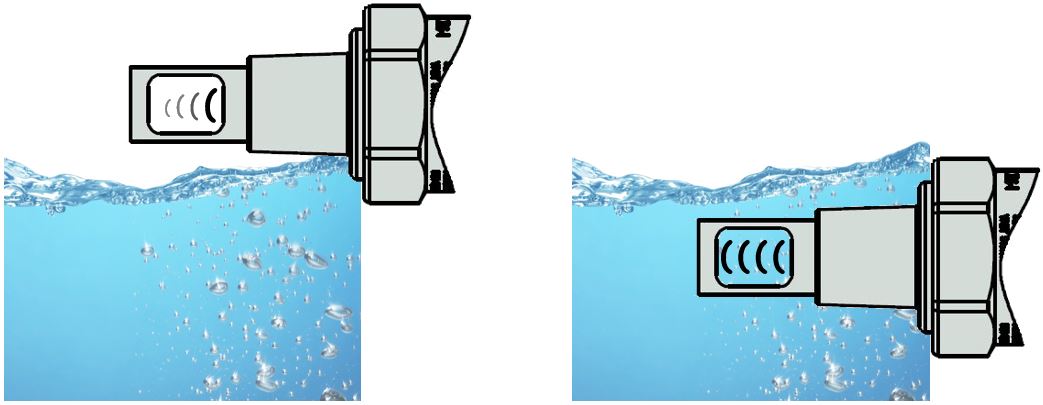

Ultrasonic point level sensors utilize ultrasonic sound waves to detect the presence of liquids. When ultrasonic sound waves are transmitted through air, they experience significant weakening. However, when the waves are transmitted through a liquid medium, they experience a substantial increase in transmission.

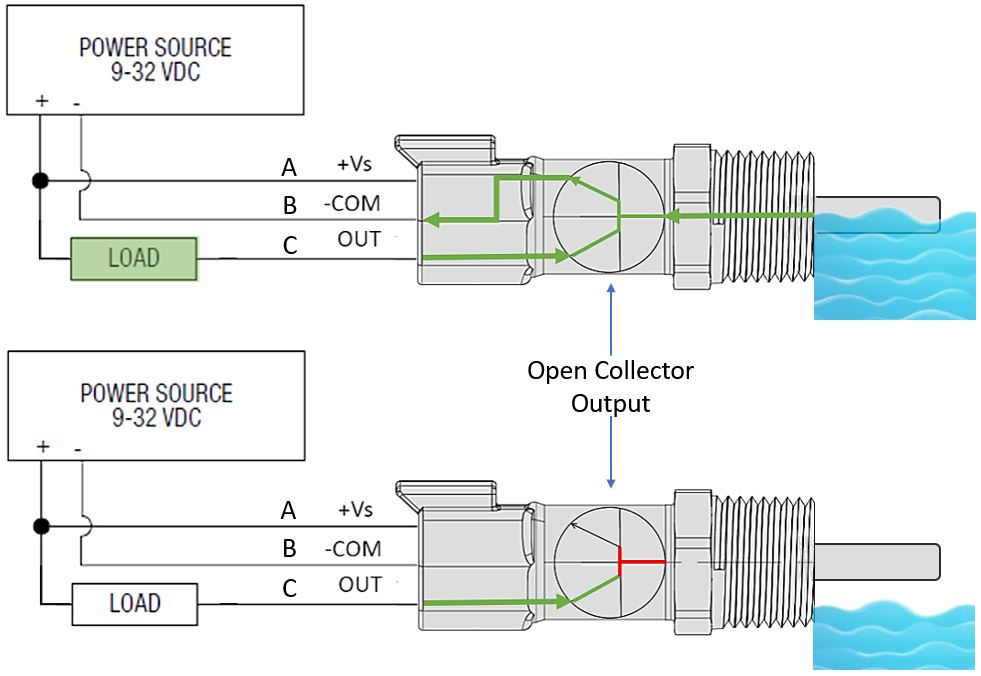

The internal electronic control unit generates electrical signals that are converted to bursts of ultrasonic energy at the sensor probe. These ultrasonic bursts are transmitted across the sensing gap. When the signal is received, the solid-state electronics generate a data-enable condition, which indicates that liquid is present (or absent). This signal energizes or de-energizes a relay or forces a solid state switch to change states.

- Mounting orientation: some require horizontal only, vertical only, or up to ± degrees without too much angle to prevent partially submerged false signals or non-signals.

- Build-up: due to the groove or channel probe design on all ultrasonic point-level sensors, mineral deposits like calcium or lime can block the sound waves.

- Viscosity: again, due to the probe design, very high viscous liquids like honey, molasses, syrups, and glycerin can remain in the probe causing false signals.

- Humidity: enough condensation caused by high humidity inside the vessel can bridge the gap for sound to easier travel and cause false signals.

- Bubbles: Foam and bubbles caused by turbulence may not be detected due to the ultrasonic design making these sensors fail in some mobile applications.

ULS-200 Advanced Capacitive Sensing

The ULS-200 is a point-level sensor with the best price-to-performance ratio and eliminates failure caused by moving parts. It works well with high viscosity liquids, high-pressure, humid environments with condensation, and reflective applications. The probe material resists coating and build up. It does not rely on specific gravity or conductivity and has optional time delays on rising or falling at no extra cost. The ULS-200 can be mounted in any full 360° orientation. It works with a wide variety of media in demanding markets such as OHV and Power Generation through high precision applications in Laboratory and Medical Device industries.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER