OHV (off-highway vehicles) like construction and agricultural equipment as well as on-road specialty vehicles like fire trucks and buses all use level sensors in some form or another.

Why Use Time Delays?

Quite often, especially in mobile applications like the ones above, a delayed output signal is needed to prevent false triggers. Turbulence and sloshing in tanks or reservoirs from a moving vehicle present a challenge for consistently monitoring the liquid levels that so many essential systems rely on.

Water-based media:

- Coolant – One of the most critical functions of any engine is the coolant system. Keeping the motor in optimal running temperature ranges is vital to protect it from overheating and irreparable damage. Consistent monitoring for low coolant levels on mobile equipment might require built-in time delays to avoid false warnings or even engine shutdowns.

- Tank level – Liquid tanker trucks carrying anything from wastewater to milk use time delays not only to prevent false alarms due to sloshing but also for fill and drain pump operation. Stopping a drain pump too soon could result in liquid being left in the tank.

- Washer fluid – Although it might not seem important at first, not having washer fluid available when you need it in dirty environments like those experienced in construction, agriculture, or military vehicles can mean reduced visibility and could lead to accidents. Time delays are used to avoid false warnings from moving vehicles.

Oil-based media/Hydrocarbons:

- Engine oil – Along with coolant, the oil level is of utmost importance. Acting as a lubricator, a barrier between moving parts, and as a cooling agent, having just the right amount of oil at all times is a must. Time delays are used to keep that annoying oil light from mistakenly coming on, so you can be confident that if it does come on, it is time to stop and investigate.

- Transmission fluid – Transmission fluid does many of the same things as engine oil in that it acts as a lubricator, a barrier, and a cooling agent for your gearbox. Many vehicles use more than one transmission for different gear sets. In emergency vehicles like fire trucks or ambulances, knowing that the trans fluid levels are correct without misleading warnings keeps from sidelining a vehicle when it could be used to save lives.

- Hydraulic oil – Construction equipment, in particular, uses hydraulics to perform many earth-moving and heavy-lifting functions. Other specialty vehicles also have hydraulic components like fire trucks, wastewater trucks, and garbage trucks. Hydraulic leaks can be catastrophic, and knowing the level at all times is needed. The extreme terrain often encountered with this equipment means a time delay should be used.

- Tank level – Just like water-based tanker trucks, there are tankers that carry oils and fuels. You’ve seen the warning signs on the back of the tank, and it is imperative that level indication is absolutely fault-proof.

How Do Time Delays Work?

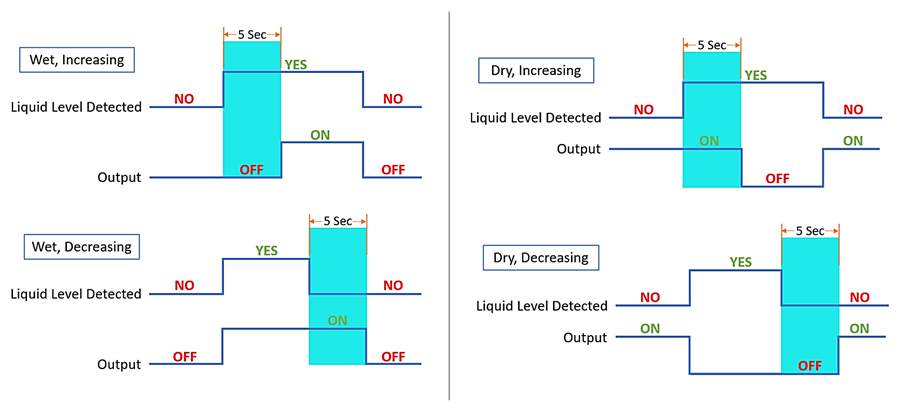

Time delay is defined as the period of time between the sensor recognizing the presence or absence of media and the sensor supplying an output signal. Time delays can be set to start on increasing level or decreasing level.

That gives us four possible combinations to configure a time delay in your point-level sensor. A visual diagram example of all four is shown below using 5 seconds as the delay duration.

Industrial relay circuits commonly use time delays as well, but these are used for functions such as timed start-up sequence control, on-off “flasher” control, and motor soft-start control. They use the same logic as the four examples above, but the descriptions are related to the contact state of the relay.

NOTC = Normally Open, Timed Closed (Wet, Increasing) | NCTO = Normally Closed, Timed Open (Dry, Increasing) |

NOTO = Normally Open, Timed Open (Wet, Decreasing) | NCTC = Normally Closed, Timed Closed (Dry, Decreasing) |

The Challenge

Finding just the right liquid point-level sensors to do the job in OHV and specialty vehicles can be challenging. Sometimes many different sensor types are required to achieve the functionality needed. Solid-state electronic circuits with no moving parts are far more suited for the demanding conditions associated with mobile equipment. Media types include water-based, oil-based, and other hydrocarbons. Harsh outdoor environments require a sealed design and robust material construction. For small restrictive spaces, you need a compact sensor with different mounting options available. As we have learned, time delays are often used with various logic configurations and with different durations depending on the application. Sometimes it can be difficult to find all these features in one sensor. Until now!

The Solution

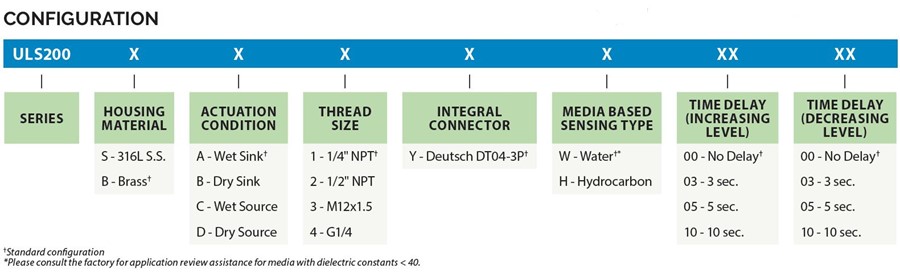

Gems’ ULS-200 solid-state point-level sensor encapsulates the best of what other sensor types offer in a single sensor. It was developed for the most rugged aqueous, oil, and hydrocarbon-based applications. The ULS-200 was made for high pressure, humidity, and harsh environments, and it resists build-up and coating, with a rugged, compact, low-intrusive design. It boasts a wide temperature range to accommodate extreme conditions. Standard configurations for Gems’ ULS-200 solid-state point level sensor include optional time delays on increasing level, decreasing level, or both. Delays to choose from include no-delay, 3 seconds, 5 seconds, or 10 seconds to fit a wide range of OHV, specialty vehicles, and other mobile equipment. Custom time delays are available for volume OEM solutions. See all of the standard configuration options below!

Want help configurating your ULS-200? Watch the how-to video below!

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER