Low Sensitivity Electronic SAFE-PAK® Relay

PRODUCT DESCRIPTION:

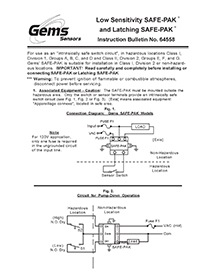

The Low Sensitivity Electronic SAFE-PAK ® eliminate the need for explosion proof enclosures. No purging is required. Sensors closures up to 1000 ohms resistance control resitive loads to 5A at 120 VAC. 120 VAC, N.O. model.

- No purging required

- Closures up to 1000 ohms resistance

- Loads to 5A at 120 VAC

FEATURED DOWNLOADS:

Features

- No purging required

- Closures up to 1000 ohms resistance

- Loads to 5A at 120 VAC

The term "intrinsically safe" refers to equipment and wiring which is incapable of releasing sufficient electrical or thermal energy under normal or abnormal conditions to cause ignition of a specific hazardous atmospheric mixture in its most easily ignited concentration. This is achieved by limiting the amount of power available to the electrical equipment in the hazardous area to a level below that which will ignite the gases present. To be certified "intrinsically safe," a device or circuit must be so designed that no two simultaneous failures can cause an explosion. In order to have a fire or explosion, fuel, oxygen and a source of ignition must be present. An intrinsically safe system assumes that fuel and oxygen are present in the atmosphere, but the system is designed such that the electrical energy or thermal energy of a particular instrument loop can never be great enough to cause ignition. Traditionally, protection from an explosion in hazardous environments has been accomplished either through the use of explosion proof conduits and enclosures (intended to contain an explosion), or via pressurization or purging (intended to isolate the explosive gas from the electrical equipment). Intrinsically safe apparatus cannot replace these methods in all applications, but in many cases can provide significant cost savings in installation and maintenance of the equipment in a hazardous area. The basic design of an intrinsic safety barrier uses Zener diodes to limit voltage, resistors to limit current and a fuse. Gems™ Intrinsically Safe Relays and Zener Barriers are approved devices designed to render any non-voltage producing sensor or switch intrinsically safe. For more information on hazardous locations as defined by the National Electrical Code (NEC) Handbook, click here.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER