Application Versatility With Warrick® Controls

Warrick® Conductivity Controls provide a dependable no-moving-parts control and monitoring of conductive liquids. Conductivity controls offer reliability, process automation, labor savings, flexibility and operator safety at economical cost. The concept is simple: take advantage of a liquid’s conductive properties to complete a circuit and cause a control relay to actuate. Use of permanently-mounted stationary electrodes gives the user precise accuracy, repeatability and no-moving-parts reliability.

System Components

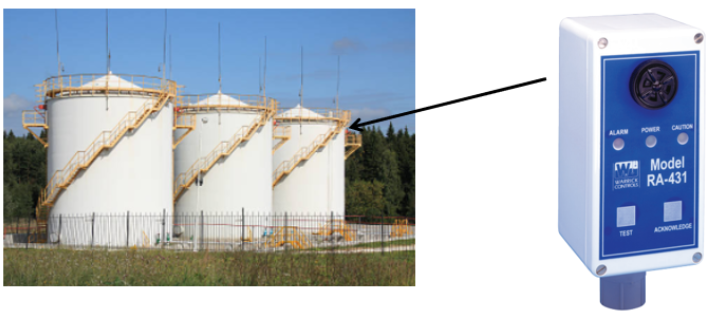

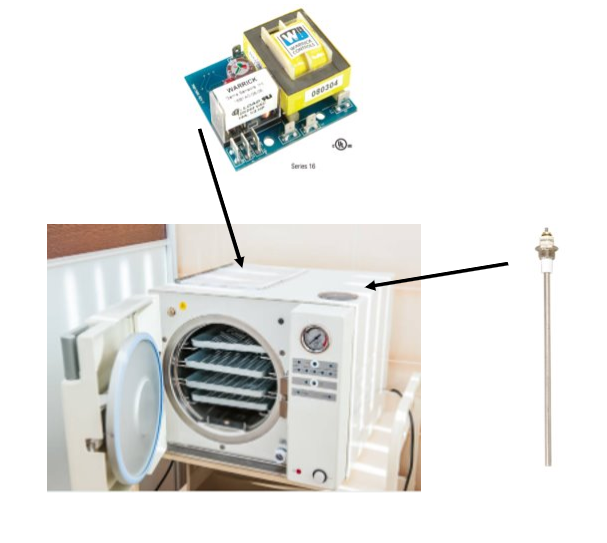

- Control/Relay: an electrical device with contacts that open and close in response to liquid levels sensed by the probes. Because it is wired directly to the power source and to the sensing source, it can send signals that activate or de-activate solenoids, pumps, alarms or pressure switch devices.

- Fitting: housing that holds the probes (or floats), insulates them from the vessel, and provides a means of connection to the control. Warrick® fittings are available for single-probe or multi-probe applications, for mounting to vessels in a variety of ways, and in open or pressure tight styles.

- Probe: a sensor that extends downward from the fitting, with the tip positioned precisely at the level where the control should be activated.

Key Applications

Learn More About Conductivity Products

Warrick® Conductivity level control systems rely on the liquid level sensing capability of probes (electrodes) that are housed inside fittings designed to accommodate one or more probes. The concept is simple: take advantage of a liquid’s conductive properties to complete a circuit and cause a control relay to actuate. These single- or multi-point sensors have no moving parts and the stainless steel corrosion-resistant electrodes can be cut to the desired length. Multiple probes per fitting allow control of several functions in less space with less expense for equipment and installation. To create a system select from numerous level controls, fittings and probe options. For OEM’s we also have the capability to custom configure liquid level control sensors and electrode fittings to meet your specific conductivity level control application requirements.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER