How Does a Coolant Level Sensor Work?

A coolant level sensor is used to detect the presence or absence of critical coolant fluid inside a coolant system. The use of coolant level sensors enables equipment uptime, ensures the proper operation, and extends the equipment service lifespan.

Typical Coolant Level Sensor Applications:

- Buses

- Fire Trucks

- Trash Removal Trucks

- Material Handlers

- Fork Lifts

- Generators

- Engines

Featured

Articles

Featured

Coolant Level Sensors

Featured

Resource Downloads

CAP-300 Product Guide

See how the CAP-300 demonstrates maximum flexibility and senses liquid and harsh chemicals while ignoring foam, coating, and condensation.

Gems Sensors Catalog, CAP-300

View the Gems Sensors & Controls CAP-300 Series catalog page.

Gems Sensors Instructions, CAP-300

Download the Gems Sensors & Controls CAP-300 installation instructions bulletin.

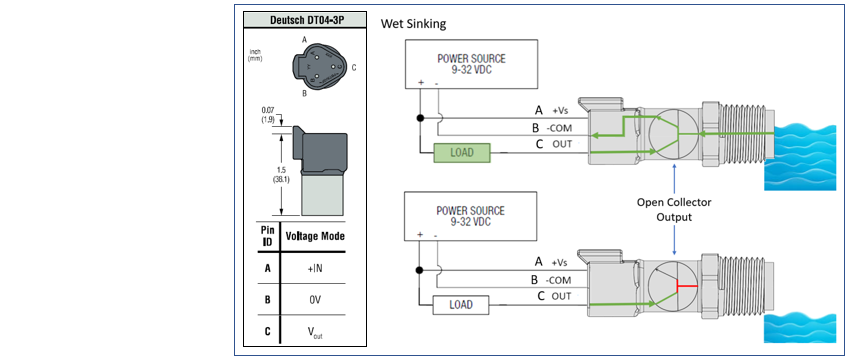

Gems Sensors Instructions, CAP-3

Download the Gems Sensors & Controls CAP-3 installation instructions bulletin.

Coolant Level Sensor FAQs:

What percentage of water and or coolant is acceptable for the CAP-300?

The CAP-300 is useable from 100% water to 100% coolant or any mixture of coolant and water.

Will density, opacity and viscosity variation as well as the accumulation of debris and chemicals found in the common coolants impair the sensor’s ability to detect the presence or absence of the medium?

It is not likely that this will affect the sensor.

If the composition of the coolant changes overtime, will the CAP-300 have to be recalibrated?

Recalibration will not be necessary if the coolant changes, the sensor will continue to operate.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER