Capacitive Operating Principle

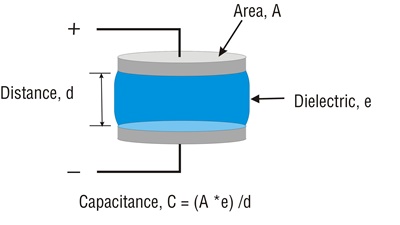

A capacitor is a two terminal device that consists of two conducting bodies separated by a non conducting (dielectric) material. A simple capacitor consisting of two plates is shown below. A simplified expression for the capacitance of this arrangement is:

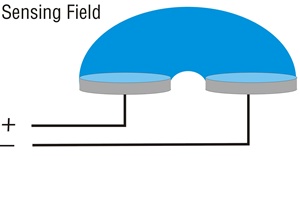

To create a more usable geometry for sensors the plates (or electrodes) can be arrayed in a variety of ways. Though this complicates the above expression for capacitance, the overall relationship between the variables remains the same. Shown below, the electrodes are arrayed on the same plane. This can be accomplished in numerous ways. The electric field is projected away from the electrodes.

If the dielectric remains constant, the capacitance also remains constant. If the dielectric changes, the capacitance naturally also changes. In capacitive proximity sensors, these two electrodes are coupled together, and integrated in a high frequency oscillator. In the “no target” state the oscillator is tuned to be resting. As a target enters the electric field, increasing the capacitance, oscillation begins. When the amplitude reaches a high enough level, a change in signal state is triggered.

Two main families of electrode configurations are utilized for standard applications:

Dielectric Type (D-Type)

Capacitive proximity sensors are configured as shown previously, with two sensing electrodes integrated in the oscillator. The sensing field projects away from the sensor face and entrance of any object into the sensing field will increase the capacitance, resulting in oscillation. Such sensors will detect all materials, insulative or conductive. These sensors are often called “shielded” and they may be flush mounted.

Conductive Type (L-Type)

Capacitive proximity sensors are configured with only one sensing electrode integrated with the oscillator. Entrance of a conductive material into the field provides the second coupling electrode which then causes oscillation. Such sensors are excellent for “looking through” an insulative material such as rubber, glass or paper in order to detect a conductive material such as water, or metal. These sensors are often called “unshielded” and they may not be flush mounted.

We also have incorporated a compensation electrode in all capacitive prox products. This electrode is integrated into the oscillator and is designed to detect contaminating elements only. Once a build-up of contaminants is detected, the effect is compensated to avoid false triggering. The ability of any electrode configuration to sense great distances is a function of the material being sensed. Sensing conductive materials results in the maximum sensing distance capabilities of any capacitive proximity sensor. The sensing capabilities for dielectric materials is a function of the dielectric constant of the material and the mass of material within the sensing field. A sensing distance reduction factor needs to be applied to such materials.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER