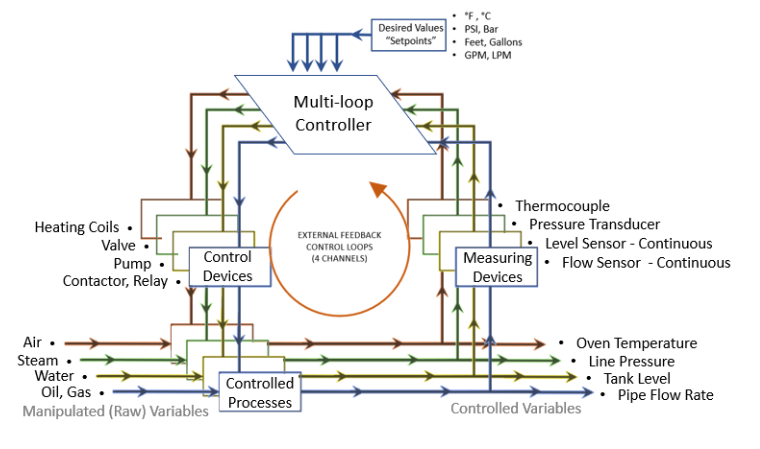

A multi-loop controller is an electronic device used in a closed loop system to read multiple input values from a number of measuring devices and provide controlled outputs to achieve and maintain separate desired setpoint values for each.

See the diagram example below:

The controlled variables are measured by suitable sensors and converted to various signals acceptable to the multiloop controller. The controller compares those measured values to the desired values (setpoints) and actuates the control devices as needed. The control devices alter the manipulated (raw) variable by changing the appropriate properties to achieve and maintain accurate and stable levels of control behavior at or near the setpoint.

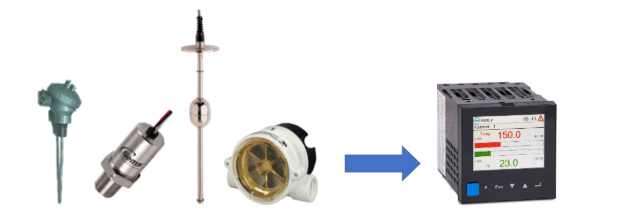

Example:

- PMA J-type Thermocouple - measures 0-350° Celsius.

- Gems 3100 Series - pressure transducer sends 4-20 mA signal for 0-40 barG.

- Gems XT-800 - continuous float level transmitter sends 4-20 mA signal for 0-152 cm.

- Gems RFA Type - flow sensor measures flow, and sends 0-10 VDC signal for appx 15-75 LPM.

PMA KS98-2 - touchscreen multi-function controller has a modular design to equip the device with the necessary inputs and outputs for reading the sensors and actuating the control devices for all four channels.

1. Temperature setpoint is maintained using a pulsed solid-state driver (SSD) output to control heating elements using proportional (PID) control method.

2. Pressure is regulated with a linear 4-20 mA output to control a servo valve.

3. Tank level is monitored, and a mechanical relay is used to start a water fill pump or drain pump.

4. Flow rate is maintained using a 0-10 VDC output to control an electronic butterfly throttling valve.

A multi-loop controller can be used where a PLC (Programmable Logic Controller) isn’t necessarily the best fit for your application. PLCs are designed to perform multiple automated tasks outside of basic process control, and on a much larger scale, while a multiloop controller is dedicated to fewer channels for control purposes only. Because of this, the multi-loop controller:

- Costs far less

- Is much easier to set up

- Can be portable or mobile

- Includes built-in display

- Is usually more accurate

- Includes features, outputs, and control options directly related to the process

Multi-loop controllers can have additional outputs and options to perform auxiliary functions:

- Alarms

- Retransmit

- Communications

- Integral Power Supply

- Remote Setpoint

- Digital Inputs

- Recorder/Datalogger

- Real-Time Clock

- Math and Logic

- And more...

Gems Sensors & Controls and West Control Solutions are happy to offer a wide range of multi-loop controllers to help with your process control needs. See more HERE.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER