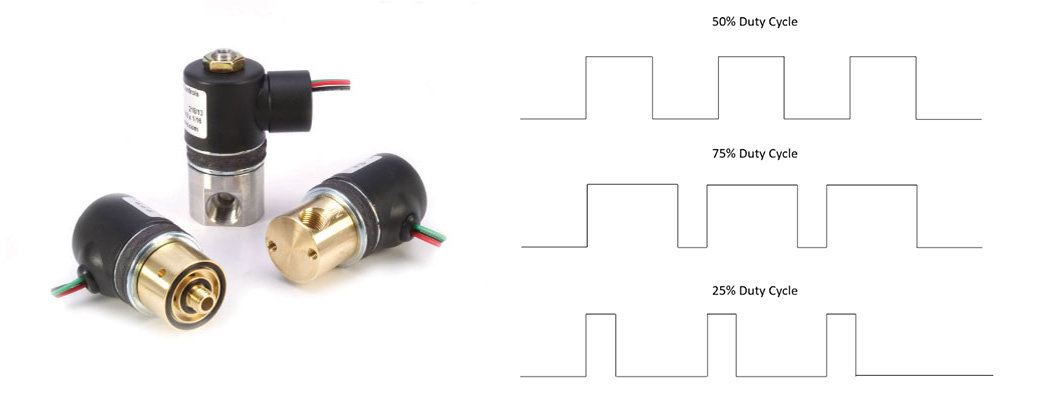

Gems Sensors Solenoid Valves are direct acting valves, which means they will be fully open or fully closed. However, did you know that you can use a Pulse Width Modulation (PWM) circuit to help control the flow more precisely? So what exactly is a PWM and how does it work?

As you know, a solenoid valve needs voltage to operate. The PWM circuit controls the voltage to the valve by breaking it up into a series of “on” and “off” pulses which varies the duty cycle. The duty cycle is the amount of time that the output voltage is “on” compared to the amount of time the output voltage is “off.” Duty cycles are measured in percentages. A 100% duty cycle would be on continuously with constant power. A 0% duty cycle would be off with no power supplied. When the duty cycle is high, this is considered more “on” then it is “off.” A 50% duty cycle means the voltage time is equally split between “on” and “off.” Below show different duty cycles ranging from 25% (low) up to 75% (high).

Therefore, by controlling the width or duration of the pulses of voltage, the length of time the valve is open is controlled, ultimately controlling the amount of flow. The longer the pulse is “on” the greater the amount of fluid will flow through the valve because the valve is open longer. The shorter the pulse is “on” the amount of flow will be less through the valve because the valve is closed longer.

Not only can the width of the pulse be controlled, but also the frequency, which is the rate at which the power supply switches from “on” and “off”. So typically, a PWM will have a duty cycle, like 75%, at a certain frequency, which is measured in Hertz. However, its important to not have the frequency faster then what the valve can handle in terms of a response rate. The valve needs time for the plunger to open or close. If the frequency is faster then the valves cycle time, the valve will not be able to open or close within the given pulse, and just remail closed. See the below diagram that explains the duty cycle versus frequency.

Did you know that PWM circuits are used throughout many different applications, not just with solenoid valves. They can be used to dim LEDs, or to help control a servo motor. If your application requires the ability to precisely control the amount of flow, consider adding a PWM circuit to your Gems Solenoid Valve.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER