Electroplating is used in many different manufacturing industries for several reasons. Since it involves plating an inexpensive metal like steel or zinc, with a nicer more expensive metal, it can save huge costs. This is crucial especially when the exterior metal is rare and difficult to work with. Electroplating also has many practical uses like preventing corrosion or providing a smoother finish. Some of the metals that are plated onto steel or zinc include copper, silver, and chromium to name a few.

The process of electroplating involves adding a metal coating on a solid metal or conductive surface. The process works like the name sounds, by applying a direct current through the solution the metal is plated. The solution is comprised of a mixture of salts and the metal that is to be plated. The inexpensive metal in the solution acts as the cathode that will receive the metal ions when the solution becomes charged, forcing the negative ions to be attracted to the cathode (metal to be plated).

The metal salt solution is crucial to the electroplating process, so it needs to be stored and measured accurately. Due to the high corrosiveness of the metal salt solution typical alloy level sensors are not chemically compatible.

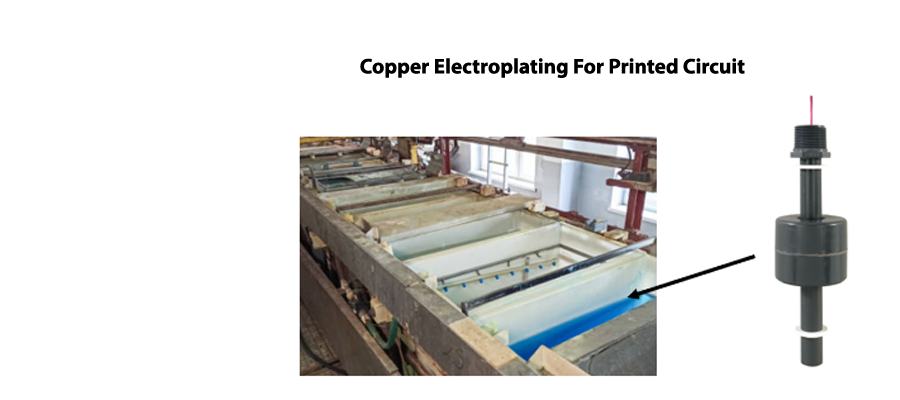

Challenge: Sourcing a high-quality level switch that is chemically compatible with electroplating metal salt solution.

Solution: Gems LSP-800 Multi-Point Level Switch

Gems LSP-800 multi-point level switch is constructed of all premium plastic components to ensure high chemical compatibility with the metal salt fluid. Specifically, the LSP-800 level sensor can be configured with either PVC, Polypropylene or PVDF, which each are very chemically inert materials. This ensures they can withstand the high salt concentration and not corrode or warp. With three different mounting styles, 1” NPT, 3” NPT and 3” 150# flange, it can be compatible with multiple different tank openings.

In addition, the LSP-800 can be configured with multiple float switches. This allows for a high- and low-level switch configuration. This configuration is ideal for an electroplating bath because they want to make sure the level is between two points. The level can then be controlled by a pump or a valve and the high and low float switches act as the pump start and pump stop. This float-based level sensor provides accurate level measurement with a 1/8” accuracy. Since this is a direct reading and not inferred (through the air technology) it is not affected by changes in temperature, pressure, or moisture in the air. This ensures a reliable level output which ensure high uptime of the electroplating process.

With a max temperature range of 210 degrees Fahrenheit (PVDF material) it can withstand being in a heated tank and still provide an accurate level measurement. Gems LSP-800 multi-point level switch is an excellent solution for measuring the metal salt solution in electroplating equipment!

Additional sensors in electroplating:

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER