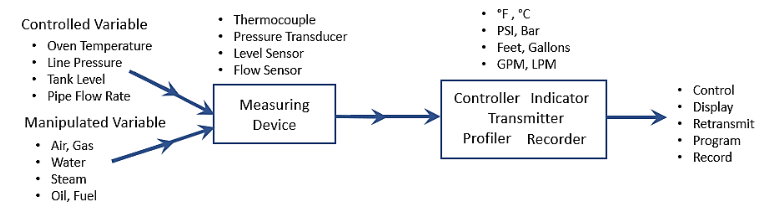

Gems Sensors are designed to measure or detect a media (air, gas, oil, water, steam etc). Sometimes it is necessary to change its properties (level, volume, flow, pressure, temperature). Other times the media properties only need to be monitored or recorded.

Sensors send an output signal to represent the measurement or detection of the media. West controllers devices receive that output and can display, record, and/or control the process to change the properties of that media to fit the application.

Gems Sensors with continuous measurement provide a linear output to represent the full range of the sensor. The most common types of linear outputs for sensors are DC voltage, current, and frequency.

West Controllers have a universal input included on most models. This accepts most of the Gems Sensors linear output types. Not all output types provided by Gems sensors are supported by West controllers, so you should verify the required output is supported.

In this example, the Gems 3100 Series Pressure Transducer is able to send DC voltage outputs of 0-5, 1-5, and 0-10 VDC, or it can send 4-20 mA (milliamp) current. These values are scaled to match the pressure range the transducer was configured for. For instance, using the 4-20 mA output for 0-750 PSIG (pounds per square inch, gauge) would cause the transducer to provide 4 mA when there is 0 PSI and 20 mA when there is 750 PSI in the container and showing on the pressure gauge. The West 6100 Plus Series Controller has the universal input where 4-20 mA is programmed, and the 0-750 scale is configured for the full range.

The same basic principle applies for the other supported linear outputs and pressure ranges. This example can be transferred to many of the other sensor types for level, flow, and temperature.

The type of sensor and controller pairing can vary depending on the application requirements:

- Pressure Transducer + Controller = controlled PSI at setpoint

- Flow Sensor + Indicator = flow rate display in GPM

- Two Pressure transducers + Transmitter with relay = Pressure differential alarm

- Level sensor + Limit Controller = latching low level safety alarm

- Flow sensor + Recorder = flow rate datalogger and gallons pumped totalizer

- Level switch + Profiler with digital input = start heating program with tank full indication

- ...And many more

It is important to note that Gems Sensors and West Controllers not only work together with the direct connections described above, but that they often work in parallel performing separate process operations on the same equipment.

Learn more about West Controllers

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER