Hot water heating accounts for around 20% or more of the average household annual energy cost within the United States. Typical hot water heaters store hot water within a tank between 120°F and 140°F. Even with no demand for hot water, the burner will energize to maintain the proper water temperature. However, the heat will eventually transfer through the tank walls, or excess heat escapes through the flue pipe. This can account for 10-20% of the annual water heating cost. One way to reduce these standby losses is to use an on-demand or tankless water heater.

Challenge: Finding a reliable flow switch to save energy costs

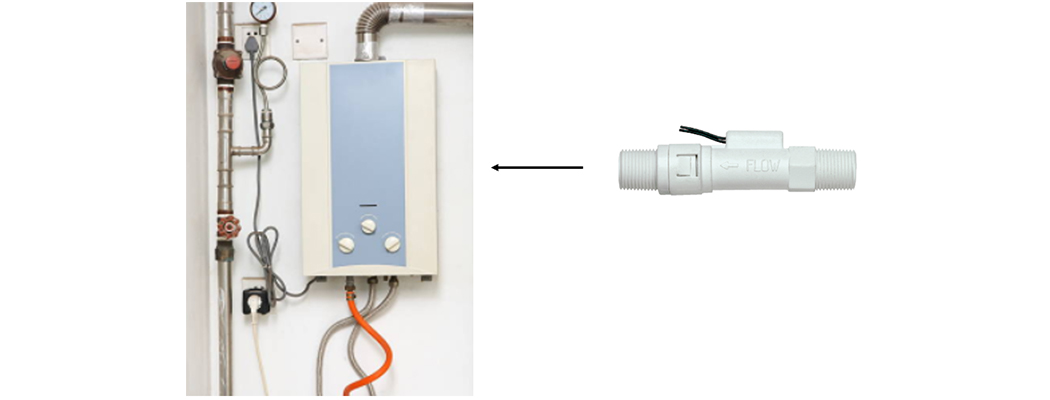

On demand hot water heaters require a flow switch to determine when there is a need for the burner to turn on. Typically the burner is off when there is no hot water usage, which helps save energy. The challenge is installing a low cost, yet reliable flow switch to signal the hot water heater to energize when there is a call for hot water.

Solution: FS-380P Inline Plastic Flow Switch

Gems FS-380P Series Inline Plastic Flow Switch has wetted material options compatible with potable water applications. This rugged industrial switch is an economical alternative to metal flow switches. This flow sensor can detect flow as low as .07 GPM, signaling the burner to energize at even the lowest demand for hot water. In addition, the inline flow switch design prevents a large pressure drop that other 90 degree flow switch designs have.

Gems' FS-380P Series Inline Plastic Flow Switch is an excellent choice with on-demand hot water heaters to help provide an endless supply of hot water.

SEARCH OUR RESOURCE CENTER

SEARCH OUR RESOURCE CENTER